fold sheet metal Sheet metal folding is bending a metal sheet to create specific angles and shapes. It involves applying force to the metal to change its geometry without altering its volume. This technique . Basically, it's some kind of tin box with what looks like ventilation holes in the back section. The front half is on hinges and opens all the way up .

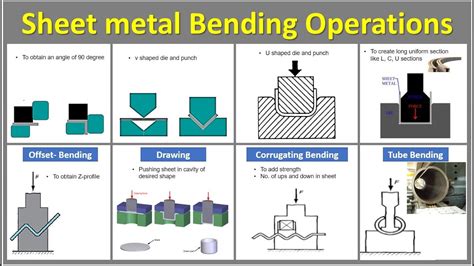

0 · types of sheet metal benders

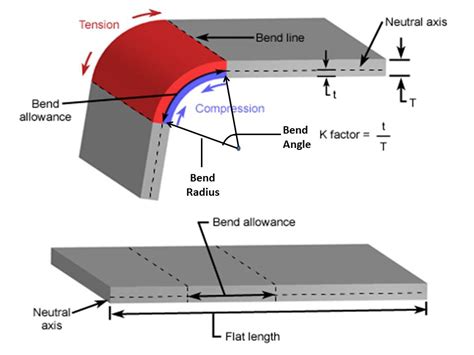

1 · sheet metal bending diagram

2 · hand bending sheet metal

3 · folding sheet metal techniques

4 · folding sheet metal at home

5 · foldable metal sheet

6 · bending tool for sheet metal

7 · 2 fold quality sheet metal

Oil canning is something you see when a metal panel appears wavy or distorted. Oil canning is an inherent characteristic of cold-rolled flat metal panels and isn’t cause for rejection but it can be an aesthetic concern in some cases.

Sheet metal folding is bending a metal sheet to create specific angles and shapes. It involves applying force to the metal to change its geometry without altering its volume. This technique . How To Bend Sheet Metal Without A Brake: How To Bend Sheet Metal Without A Brake in 4 different methods with minimal or homemade tools. .more.This size allows my students to practice their layout pattern and folding on paper before they move to metal. If your plan works on a paper mock up it should work on sheet metal. I've included a picture and a pdf file of the plans I use in my .You can do a lot with only a handful of tools. Even still, it can be pretty easy to mangle if you don’t use the right technique. Here are a few tips that will let you make accurate, clean, and professional-looking bends when you’re working .

The purpose of sheet metal folding is to quickly form large pieces of steel into a bespoke shape using robust machinery. It would be impossible to create the right shape without this process.We are Palmerston North’s sheetmetal and light engineering specialists. For all your sheetmetal and light engineering needs, we are the people to talk to.

We think of sheet metal fabrication as an art form. It’s important to us to be creative in what we do. . The Fold was born out of a career in the roofing industry. Over the years it became apparent there was need for a sheet metal fabrication shop in the Northern Colorado area. We are proud to be located in beautiful Loveland, Colorado . The fold tool in sheet metal seems to want a new sketch for each fold line. Is there a way to fold this part using the existing construction lines in the sketch? Thank you. Autodesk Inventor Professional 2024 64-Bit Edition Build .

types of sheet metal benders

Hi all, I am going to attempt to do as much of the body work on GPW 225290 as i can- my welding is getting better and i have been collecting some tools, reading and been inspired by others here on the G in the past few years doing alot of their own body work.Sheet Metal Box: This is a great project to make if you are new to working with sheet metal. At this point in my class all of our sheet metal projects have been very simple with, at most, one bend. . Also, you will need to move some teeth on your break or you will not be able to fold your metal correctly. Move the teeth on your break around . However, I noticed it’s not easy to find a way to (un)fold/ bend sheet metal, in order to create 2D drawings. Am I missing anything? Can anyone advise how this can be done with the Make or Pro version? Thanks. Anyone doing sheet metal? DaveR September 22, 2020, 7:18pm 2. Can you show an example model that you want to unfold? .

Flexible Modeling. In Onshape, you can initiate a sheet metal design using several methods: you can convert a solid part into sheet metal; design from a flat sketch, then fold; use flange tools to add edges and features; or directly import and adapt existing sheet metal designs.

The Fold/Unfold functionality enables you to produce a flat blank of any part that includes cylindrical and conical bends, and to fold any planar part that includes planar bend areas with orthogonal side faces. This functionality facilitates the design of multiple-bend parts such as sheet metal parts made by progressive die operations. I have a recurring problem. For example I draw a rectangle 150mm x 122mm: I extrude it to 0.7mm I create a 2D sketch and draw a simple line that ends on the edges of the rectangle. I go into "Sheet Metal" and click "fold" I choose "Bend Line" and then choose the line I drew in 2D sketch. i clic.Fold sheet metal is an excellent option for SolidWorks users because it allows them to create complex shapes quickly. The benefits of using fold sheet metal in SolidWorks are: - It allows the user to create complex shapes with ease - It allows for more control over the design process, as well as provides a number of design options that can be . Bending is one of the most common sheet metal fabrication operations. Also known as press braking, flanging, die bending, folding and edging, this method is used to deform a material to an angular shape.. This is done through the application of force on a workpiece. The force must exceed the material’s yield strength to achieve plastic deformation.

In this quick tutorial, we explain how to use some of the sheet metal tools in SOLIDWORKS, specifically the Fold and Unfold tools. First, let’s set up our base flange, being sure to have a fully defined sketch to start. After creating a base flange, find the Fold and Unfold tools in the Sheet Metal tab in the CommandManager. It is often much .Folding Sheet Metal: If you're like me, the shop is full of tools.too full. I have always wanted a press brake for bending sheet metal, but it takes up too much space. Without it, bending sheet metal on a nice straight and tight line is deceptively difficult. In this . Folding sheet metal. SketchUp. visaltp June 21, 2022, 2:00pm 21. Hello there. I was searching how to unfold sheet metal parts similar way. The problem I found that if you unfold along outer circumference means you are adding the thickness to the dimensions of the component end there will be an length/width will be long by thickness of material.

Sheet metal is extremely handy for all kinds of jobs since it’s so easy to work with. You can do a lot with only a handful of tools. . You also get a nice round fold, since the 2×4’s will have a radius which will transfer to the sheet metal – your .CIDAN Machinery Group is proud to be the world-wide industry leading source for sheet metal folders and metal bending machines. . and efficient ways to bend sheet metal into various forms. We provide high-performance, automated . These software provide sheet metal modules or related functions that can help designers with the design and unfolding calculations of sheet metal parts. Use the sheet metal module or tools in the software: Most 3D CAD .

Hi, First time using the sheet metal feature. I recreated my original part into a flat design (I would be interested in knowing if I could have unfolded my original design somehow, Unwrap gave nothing good). My part would be rolled around a 18mm cylinder. how can I fold/ roll it? I am unsure if Bend or Fold would achieve the shape I seek.

12 Inch Sheet Metal Folding Tool - Ultimate HVAC Sheet Metal Bender, Hand Seamer, Metal Forming Tool for Duct Work & Metal Roofing; Premier Sheet Metal Folding Bar & Bending Tool for Professionals. 4.1 out of 5 stars. 3. .99 $ 17. 99. FREE .

Malco TS1 Turbo Shear 20 Gauge Capacity Sheet Metal Cutting Attachment. .68 $ 61. 68. Get it as soon as Tuesday, Nov 5. In Stock. Ships from and sold by Amazon.com. + Malco 24F 24 in. Folding Tool. .99 $ 30. 99. . HURRICANE 12 Inch Folding Tool, Sheet Metal Bending Tools for HVAC, Duct Bender Hand Tool, Forming Metal .Laser cutting patterns for folding/bending sheet metal So I wan't to make a metal box for a project and I have access to a laser cutter and any sheet metal thicknesses I need - 0.5 to 12mm and everything in between. I don't have a brake press and don't want to pay for folding - so by hand it is. The question - are there any guidelines on what . Buy Vekkia Sheet Music Stand-Metal Professional Portable Perforated Music Stand with Carrying Bag,Folding Adjustable Music Holder,Super Sturdy suitable for Instrumental Performance & Band & Travel: Musical Instruments - Amazon.com FREE DELIVERY possible on eligible purchases . On-Stage SM7211B Professional Grade Folding Orchestral Sheet Music .

Laser and Fold Capabilities. Hendon Sheet Metal uses modern computer controlled laser cutting and Folding technologies to get your sheetmetal products right first time, every time. Contact us now for a quote! Our de-burring and edge rounding kit. Discover our Mitsubishi EX-F . I am trying to make a sheet metal part that has flanges folded down on one side and then folds running orthogonal to those flanges to make a somewhat curved have tunnel if you will. See model. Inventor 2018 won't let me make the folds on the face I previously folded the flanges from. What should I d.

sheet metal bending diagram

Metal folders, also known as folding machines, are essential tools in the metal fabrication industry. These machines are designed to bend and fold sheet metal into various shapes and angles, making them indispensable for creating precise and .

Learn how to use a straight handle hand seamer to bend sheet metal.Learn about--Sheet metal gauges-Types of hand seamersSign up for the email list. Grab some.2-Fold – Quality Sheet Metal & Fabrication Brisbane. Simplify installation and keep your costs low with our custom design and fabrication solutions. SEE OUR PRODUCTS. . Sheet Metal Flashings. A huge variety of materials and designs c ustom made to suit any project. Rainwater Goods. Fascia, guttering, downpipes, rainwater heads, and more.

sheet metal nh

hand bending sheet metal

Lancing is a type of punching operation where the workpiece is sheared and bent with one strike of the lancing tool. It creates features like tabs, vents, and louvers in sheet metal workpieces. The nibbling process involves cutting a sheet metal .

fold sheet metal|sheet metal bending diagram